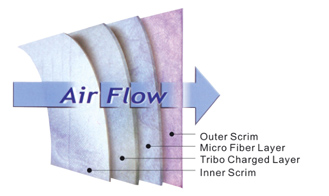

Actifil Medium Efficiency Particulate Filter Media is a composite synthetic media that's ideally suited for pocket filters, rigid box filters, and other filter applications, pleated and non-pleated. Its advanced gradient structure uses four different layers of nonwoven material. As a result, this synthetic media provides a unique combination of advantages:

The four layers of nonwoven media, from upstream to downstream are:

Ultrasonically Sealed Edges: Actifil Pocket Filter Media is ultrasonically sealed on both edges for maximum burst strength and no-bypass performance. Your company logo may be embossed along the edges to enhance the aesthetics and marketing value of the filter.

Ultrasonically Welded Spacer: Six strips of high strength spun bond nonwoven are continuously welded inside the pockets. These spacers prevent adjacent pockets from obstructing one another due to over-expansion.